In the bustling, high-stakes environment of modern warehouses and distribution centers, the forklift is the indispensable workhorse. However, its operation presents significant risks, including accidents with pedestrians, damage to inventory and infrastructure, and inefficient workflows. Addressing these challenges requires technology built specifically for this unique mobile environment. This is where a specialized Forklift MDVR (Mobile Digital Video Recorder) becomes a game-changer. Unlike generic vehicle recorders, a system like the DVRF04H is engineered from the ground up to meet the distinct demands of forklift operations. A robust Forklift MDVR integrates high-definition video recording, advanced stability features, and intelligent analytics to create a safer, more efficient, and accountable warehouse ecosystem. This comprehensive guide will explore the critical technologies that make the DVRF04H MDVR an essential tool for any business relying on forklifts, focusing on how its tailored design mitigates risks and optimizes performance right from the warehouse floor.

Engineered for Stability: How the Forklift MDVR Withstands the Unique Challenges of Material Handling

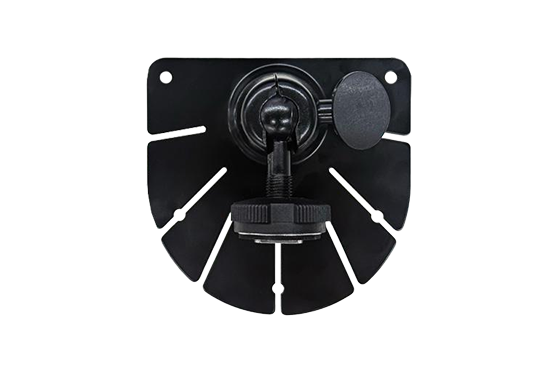

The operational environment of a forklift is uniquely harsh, characterized by constant jarring from lifting heavy loads, navigating tight spaces, and traveling over dock plates and uneven flooring. A standard commercial DVR would quickly fail under these conditions. The DVRF04H Forklift MDVR incorporates specific engineering solutions to ensure flawless performance where it matters most.

- Industrial Anti-Vibration Architecture for Forklifts: The core of the DVRF04H's design is an industrial-grade anti-vibration framework that goes beyond general vehicle protection. It is calibrated to dampen the specific shock frequencies generated by a forklift's mast movements, the dropping of pallets, and the abrupt stops and starts common in warehouse traffic. This specialized hardening prevents internal components from becoming dislodged and, most critically, ensures the continuous integrity of data being written to the storage card. For a Forklift MDVR, data loss due to vibration isn't just an inconvenience; it could mean the loss of crucial footage needed to investigate a near-miss or a major accident, directly impacting liability and safety protocols. This robust construction makes the DVRF04H an reliable witness in the dynamic and demanding world of material handling.

- Durability in Industrial Settings: Wide Temperature and IP67 Sealing: Warehouses can be extreme environments, from refrigerated cold storage facilities to non-climate-controlled spaces that become sweltering in summer. The Forklift MDVR DVRF04H is built with a wide operating temperature range (-30°C to 70°C) to perform reliably in these varied conditions, ensuring continuous operation whether the forklift is working in a freezer section or a loading dock. Furthermore, its IP67-rated enclosure is vital for forklift applications. This high level of ingress protection guards against pervasive industrial dust generated from cardboard and packaging materials, as well as moisture from cleaning processes or accidental spills. This resilience ensures that the MDVR remains operational, protecting your investment and maintaining a constant record of forklift activity.

Advanced Power Management Tailored for Forklift Electrical Systems

Forklifts, particularly electric models, have complex power cycles involving frequent charging and high-draw operations from lifting hydraulics. The DVRF04H Forklift MDVR is designed with sophisticated power management to handle these specifics.

- Compatibility with Forklift Power Voltage: The MDVR supports a wide voltage input (9-36V), making it compatible with various forklift power systems. More importantly, it includes advanced filtering to protect against the voltage fluctuations and electrical noise that can occur when the forklift's hydraulic pump engages or disengages. This clean power supply is essential for maintaining stable video encoding and protecting the internal storage from corruption.

- Forklift-Specific Power Loss Protection: In a warehouse, a forklift might be turned off abruptly at the end of a shift or involved in an incident that causes a power disconnection. The DVRF04H's integrated power loss protection (PLP) system, often using a supercapacitor, provides enough emergency power to properly finalize the video file being recorded at the moment of shutdown. This ensures that the last few seconds of footage—often the most critical for understanding an event—are saved completely and are not corrupted. This feature is non-negotiable for a Forklift MDVR used in accident investigation and operational auditing.

High-Definition Video for Clear Visibility in Complex Warehouse Environments

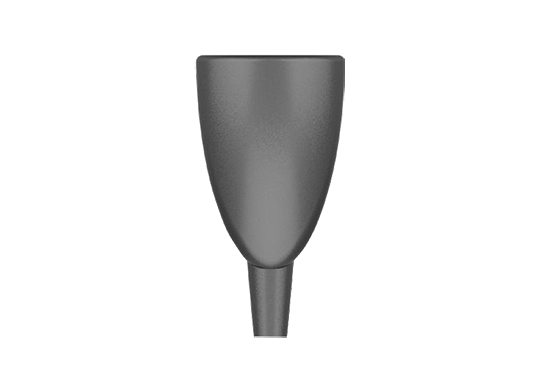

The primary role of the Forklift MDVR is to provide a clear visual record, but the challenges of a warehouse—poor lighting, tight aisles, and blind spots—demand superior video technology.

- Optimized Video Compression for Storage Efficiency: Using advanced H.265 encoding, the DVRF04H captures high-resolution 1080p video while minimizing storage needs. This is crucial for forklift operations that may run multiple shifts. The efficient compression allows for longer recording periods on a single memory card, ensuring that footage from an entire work cycle is available for review without requiring frequent manual downloads or large, expensive storage arrays.

- Secure and Reliable Storage for Evidence Integrity: The Forklift MDVR supports high-capacity, industrial-grade microSD cards designed for continuous read/write cycles. To maintain the integrity of footage for potential legal or insurance purposes, the system can employ video encryption. This prevents tampering and establishes a secure chain of custody, making the recordings from the DVRF04H admissible as evidence. This is a critical feature for a Forklift MDVR tasked with providing undeniable proof in incident analyses.

Intelligent Features Designed for Forklift Safety and Operational Efficiency

Modern Forklift MDVR systems like the DVRF04H incorporate smart features that actively prevent accidents and improve workflow, moving beyond passive recording.

- AI-Powered Pedestrian Detection and Blind Spot Monitoring: This is a cornerstone of forklift safety. The MDVR uses sophisticated computer vision algorithms to analyze the camera feed in real-time. It can detect pedestrians entering predefined danger zones around the forklift and issue an immediate audible and visual alarm to the operator. This proactive warning system is invaluable in preventing collisions in busy aisles. Similarly, blind spot monitoring uses additional cameras to cover areas the driver cannot see, providing a comprehensive safety net.

- Operator Behavior Monitoring via Integrated Sensors: By connecting to the forklift's sensors via available interfaces like CAN bus or I/O ports, the Forklift MDVR can monitor and record operator behavior. It can detect events such as seatbelt unbuckling, improper lifting techniques, or impacts (via a G-sensor). This data is not for punitive measures but for constructive coaching, helping to identify training opportunities and reinforce safe operating procedures, ultimately reducing accident rates and associated costs.

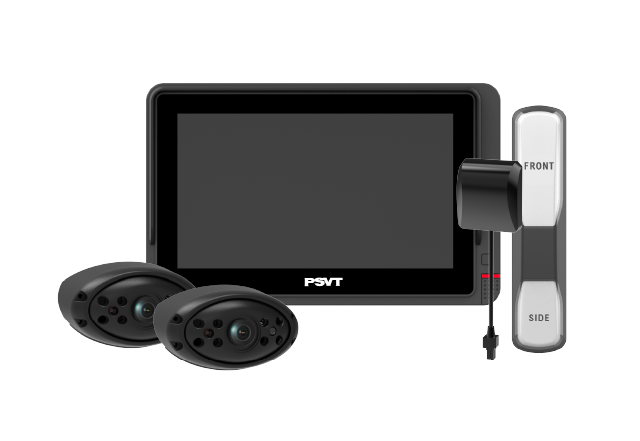

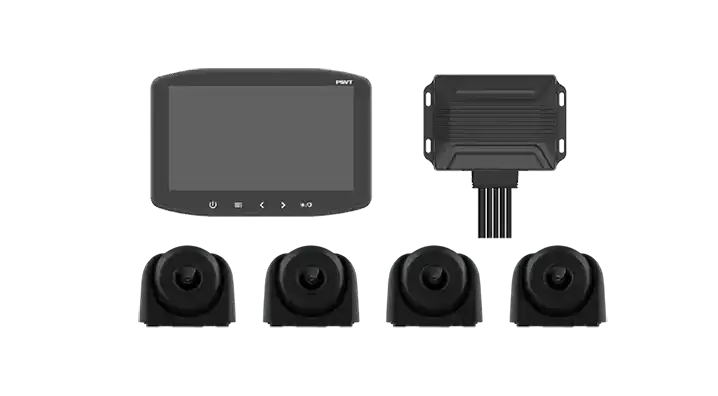

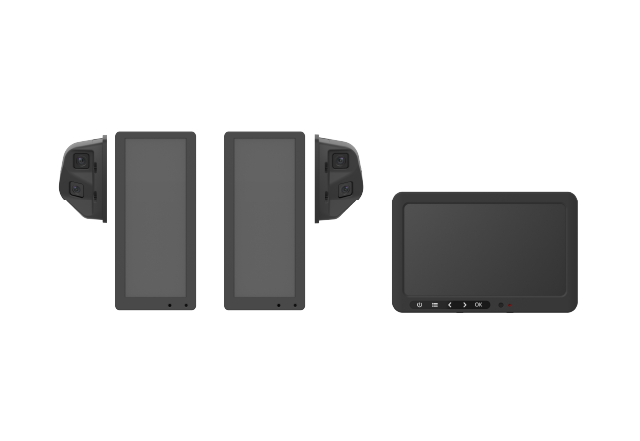

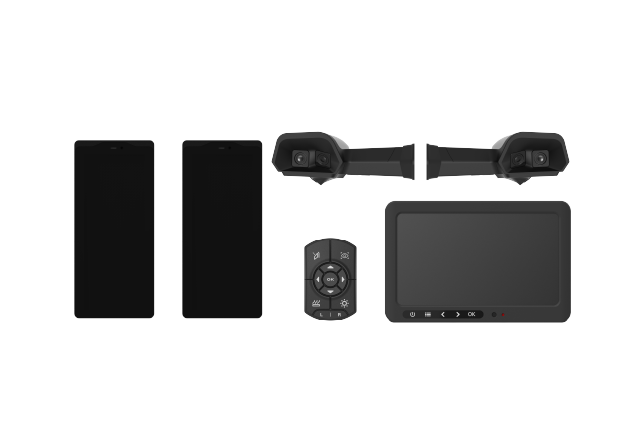

Multi-Channel Camera System for Complete Forklift Coverage

A single camera is insufficient for the complex operational environment of a forklift. The DVRF04H supports multiple camera channels to provide a complete view.

Comprehensive Camera Views: A typical Forklift MDVR setup using the DVRF04H would include:

- Forward-Facing Camera: Records the path of travel and load handling.

- Operator-Facing Camera: Monitors driver alertness and compliance with procedures.

- Rear-View or Mast Camera: Covers blind spots behind the forklift and provides a view of the load placement.

- Right-Side Camera: Monitors the aisle and pedestrian traffic on the operator's blind side.This 360-degree coverage ensures that every aspect of the forklift's operation is documented, from the operator's actions to the surrounding environment.

Integration with Warehouse Management Systems (WMS) and Telematics

The true value of a Forklift MDVR is realized when its data is integrated into broader operational systems.

- Data for Operational Analytics: The DVRF04H can provide valuable data on forklift utilization, travel paths, and idle times. When combined with warehouse management software, this data can help optimize layout, improve picking routes, and ensure efficient asset allocation.

- Real-Time Location and Geofencing: With an integrated GPS module, the Forklift MDVR enables real-time tracking of forklifts within the warehouse yard or a large distribution center. Managers can set geofences to receive alerts if a forklift enters a restricted area, enhancing security and operational control.

In conclusion, the DVRF04H represents a significant evolution in warehouse safety technology. It is not merely a recording device but a comprehensive Forklift MDVR system designed to proactively manage risk, enhance efficiency, and protect valuable assets. By investing in a specialized solution that understands the unique challenges of forklift operation, businesses can foster a culture of safety, reduce operational costs, and build a more resilient and productive supply chain. The integration of stability, intelligence, and connectivity in the DVRF04H makes it an indispensable component of the modern, smart warehouse.