Reverse camera systems, also known as rear visibility systems, have transitioned from an optional luxury feature to an essential safety component in modern vehicles, particularly in heavy-duty trucks and commercial vehicles. The widespread adoption of these systems is driven by the societal consensus of zero tolerance for accidents caused by "blind spots" and the strong push from governments worldwide for mandatory regulations. This article will delve into the technical definition, the significance for heavy-duty trucks, and the milestones of reverse camera system standardization.

Technical Definition and Functionality of Reverse Camera Systems

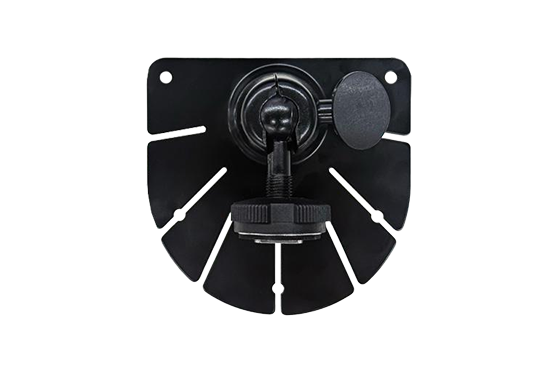

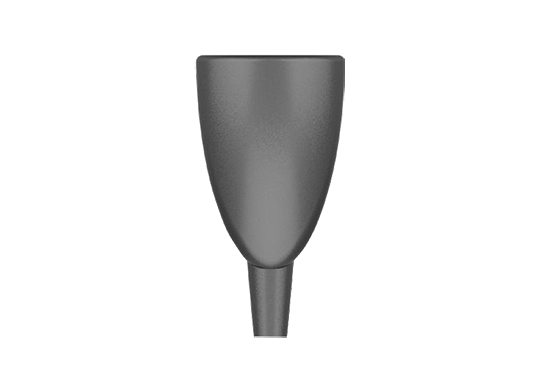

Reverse camera systems are designed to provide drivers with real-time, graphical visibility of the vehicle's rear area. These systems consist of several core components. The wide-angle camera is positioned at the rear central part of the vehicle, typically near the license plate or bumper. This camera uses low-light CMOS or CCD sensors to capture a wide field of view (typically over 130 degrees), allowing it to cover the rear area comprehensively. The image processing unit receives and processes raw video signals from the camera, performing distortion corrections, optimizing brightness, and superimposing digital elements such as parking guidance lines. The display interface is integrated into the vehicle’s central infotainment screen or a dedicated rearview mirror display, offering the driver a clear view of the rear area. Lastly, the trigger logic ensures that the system is automatically activated when the vehicle’s transmission is shifted into reverse ("R" gear), displaying the camera feed.

To meet regulatory standards and practical demands, reverse camera systems must meet specific performance guarantees. The system’s field of view (FoV) should cover a rear area of at least 10 feet by 20 feet (approximately 3 meters by 6 meters), ensuring visibility of potential obstacles and pedestrians. Additionally, the image quality and response time must be clear and free of delay, meeting minimum resolution standards to enable quick and accurate decision-making by the driver.

The Critical Need for Reverse Cameras in Heavy-Duty Trucks

While reverse camera systems are necessary for passenger vehicles, their importance escalates for heavy-duty trucks and large commercial vehicles. These vehicles typically face much larger rear blind spots, which are caused by their high body structure and boxy design. The driver’s seat height makes it difficult to spot close-range ground targets such as children, pets, or low-lying obstacles. Furthermore, the vehicle length and width create significant challenges for traditional rearview mirrors to provide adequate coverage, particularly when maneuvering in tight spaces.

Heavy-duty trucks often operate in confined spaces, such as logistics hubs, loading docks, construction sites, or narrow city alleyways. In these environments, having clear rear visibility is essential to avoid structural collisions, which could damage the truck, its cargo, or nearby infrastructure. The system is also critical for pedestrian and worker safety in busy industrial areas, where it directly helps prevent accidents involving ground personnel.

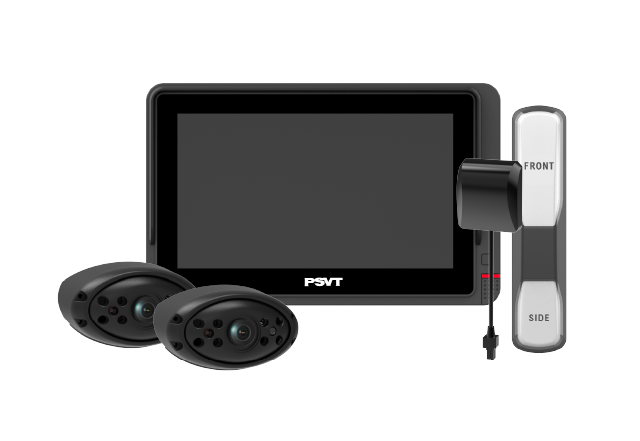

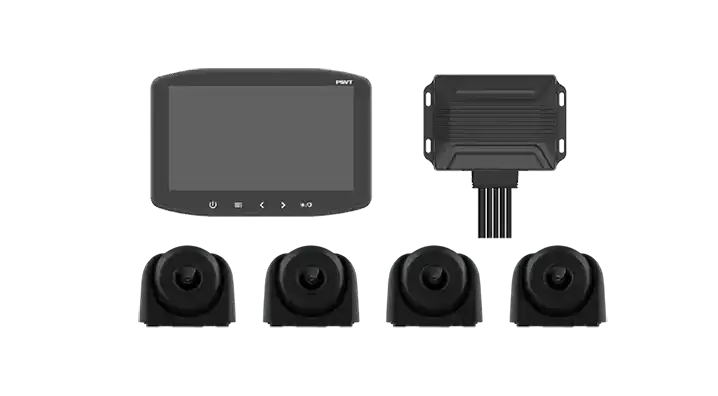

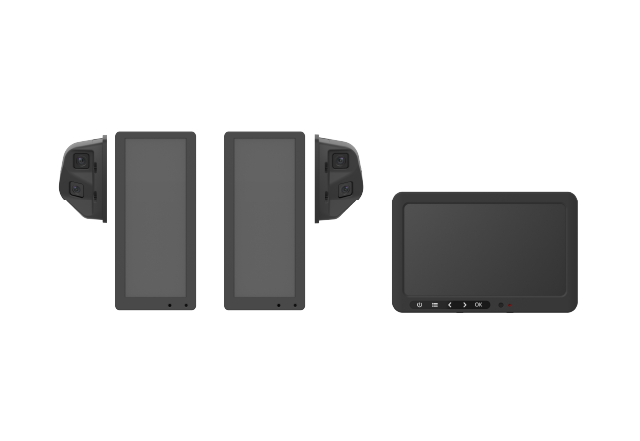

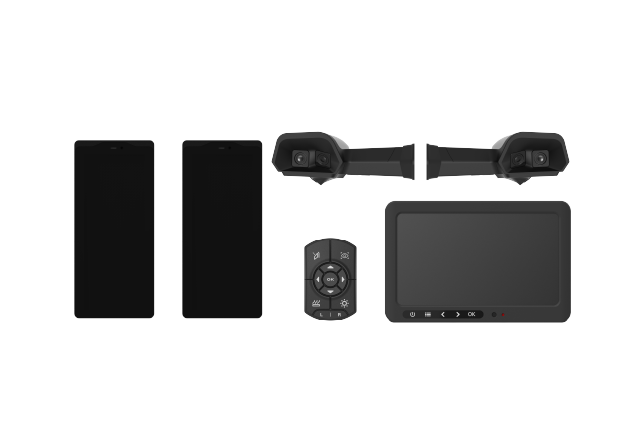

Modern heavy-duty trucks integrate reverse cameras as part of a larger ADAS package, combining the reverse camera with technologies like millimeter-wave radar and ultrasonic sensors, which offer precise distance and speed measurements. The 360-degree around-view monitor system further enhances safety by using multiple cameras to create a bird’s-eye view of the truck’s surroundings, aiding in tight-space maneuvering.

The Standardization of Reverse Camera Systems: Regulations and Timelines

The evolution of reverse camera systems from an optional feature to a mandatory safety component has been primarily driven by regulations in North America and Europe.

In the United States, the mandatory adoption of reverse camera systems can be traced back to legislative efforts aimed at protecting children. The Cameron Gulbransen Act of 2007 authorized the National Highway Traffic Safety Administration (NHTSA) to establish rear visibility standards. In March 2014, the NHTSA finalized rules establishing minimum rear visibility coverage requirements, mandating that all new vehicles under 10,000 lbs (4536 kg) be equipped with reverse cameras by May 1, 2018. This milestone marked the full standardization of reverse cameras in North America’s passenger and light commercial vehicle markets.

Following suit, other regions have adopted similar regulations. In Canada, regulations were synchronized with those of the U.S. in May 2018. In the European Union, the General Safety Regulation (GSR) came into effect on July 6, 2022, requiring new vehicles to include either reverse cameras or detection systems. Australia plans to gradually enforce the same requirement by November 1, 2025.

Conclusion: A Safety-Driven Industry Transformation

The standardization of reverse camera systems represents a significant milestone in automotive safety technology. From their debut in concept vehicles in 1956 to becoming a mandatory feature in North America by 2018, reverse cameras have evolved in response to public safety concerns and legislative action. For the heavy-duty truck sector, reverse cameras are not just a regulatory requirement; they are vital safety tools that enhance operational efficiency, reduce accident costs, and fulfill societal safety obligations.

As autonomous driving technology continues to develop, reverse camera systems will remain an essential environmental sensing component, playing a key role in vehicle positioning and decision-making systems. The 360 reverse camera for commercial vehicle offers a comprehensive view of the surroundings, facilitating safer parking and maneuvering. When integrated with a reverse camera 360-degree system, it provides a complete bird’s-eye view of the vehicle’s environment, improving safety in both personal and commercial vehicle operations.